Taking steps: lowering the carbon footprint of today’s cold chain

Stark numbers

Then there’s the refrigerated transport underpinning today’s global cold chains. Where another study, this time focused on the pharma sector, has calculated that refrigerated transport consumes 20% more fuel than other heavy vehicle types. That number seems incredibly high, but there is a very good reason. Refrigerated transport protects the cargo at all times, in all the different ambient conditions a container may find itself over the course of a delivery. That task can only be achieved through active refrigeration. And that consumes power, there is simply no way around that.

So, 20% more fuel consumption. A stark number indeed. And this at a time when it’s calculated that there are 4 million refrigerated road vehicles worldwide (accounting for about 10% of all new trailer registrations in Europe), and around 1.6 million refrigerated containers of various ages.

Yet amidst the not uplifting news has long been a huge opportunity to massively boost the efficiency of cold chains, and to cut fuel usage and associated carbon emissions. The question, of course, is how?

Contributing factors

Finding the right answer involves a number of different, if interconnected factors, with two in particular standing out:

- There is of course a technology factor, with leading vendors such as Thermo King investing heavily in new innovations to continue pushing the boundaries of sustainability in transport refrigeration

- In addition, there is the choice factor guiding the mode of transportation used by supply chains – a decision that traditionally has been based around the needs of cost versus urgency, but is now increasingly being influenced by wider sustainability concerns

This latter point relates in part to the need for behavioral change mixed with better planning, to enable where possible the use of (ultimately) slower, however more sustainable and much more energy-efficient options. The obvious example here being the ability to avoid air transport for moving loads, which – while taking eight hours to fly a load from Brussels to New York, compared to 15 days by sea – is approximately 50x more CO2 intensive than multi-modal journeys

Focusing the attention

Multimodal is mentioned above because it is proving to be the most sustainable option for moving loads across the cold chain, from the place of manufacture, via road, rail and vessel, to distribution centers and beyond.

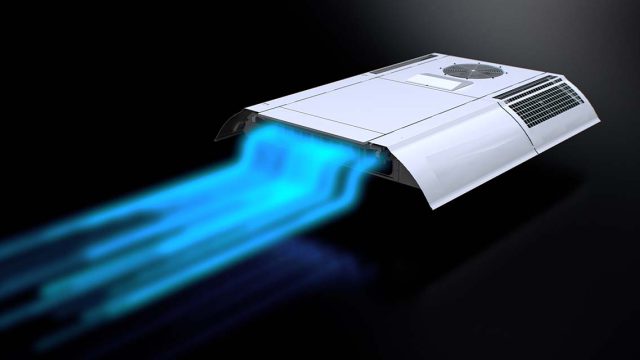

A task that is inspiring companies like Thermo King to look at all aspects of the multimodal journey to identify every possible option to cut energy usage, particulate matters and potential food waste. Our efforts in particular are focused on three distinct areas:

Enhancing Power consumption

Over the past decade, Thermo King has developed an entire product line of innovative marine transport refrigeration units and gensets – including the CSR, Magnum, Magnum Plus, SG-3000e and SG-5000. The newest marine reefer technology is the CFF model (Container Fresh & Frozen), that uses 20% less energy without ever compromising the cargo’s required in-range temperature requirements.

This we calculate can represent a net fuel saving of up to $50 per container per trip. Scale that up to daily global shipping volumes, and the efficiencies delivered soon become hugely significant. Better still, the sustainability savings can be further enhanced with the use of R513A refrigerant to cut back any unit’s global warming potential.

Perfecting temperature control

Depending upon the item being transported, be it food, pharmaceutical products, or high-tech components etc., every container load demands a unique set point be achieved and maintained. In food for example, this can range from +30° to -70°C, with minimal variation to set point, and any break in this cold chain link can quickly lead to food wastage (which alone accounts for 6% of global GHG emissions).

As it comes to pharmaceuticals maintaining Good Distribution Practices (GDP) first means precise temperature control, with Thermo King as a best-in-class example limiting temperature fluctuations to +/- 1°C for frozen loads, and +/-0.25°C for chilled loads throughout any journey, means protecting the cargo. But equally, it’s also about being proactive through telematics. Where any change in temperature can be instantly identified and rectified to save loads, while also maintaining a clear ‘audit trail’ of temperature ranges from cargo loading to unloading. Thermo King offers datalogger provides full transparency on temperatures, humidity, power consumption and events.

Maintaining optimal equipment condition

Transport refrigeration equipment is complex machinery, moved across multimodal modes, with rough handling, that will feel the effects of wear and tear over time. It therefore requires regular servicing and maintenance to keep in optimal conditions, and when this doesn’t happen it’s easy to see how older equipment can gain a reputation for being a source of environmental pollution.

For multimodal journeys, Thermo King has worked hard to make our containers as durable as possible to withstand the harshest of conditions. We’ve also achieved market leading reliability, and back this up with the installation of telematics devices that report on the conditions of individual units and containers. As a result, it’s far easier to introduce proactive maintenance, use of patented SMART PTI software, schedules to address potential faults or emerging issues – before they become a problem.

Enhance your multi-modal capabilities

With refrigeration units from Thermo King, it’s possible to see the cutting edge of sustainable technology in play, giving customers the ability to deliver chilled, fresh and frozen cargo around the world.

To discover more, you can view our complete range here.

Other relevant articles that might interest you

Marine

(Don’t) let it breathe: regulating fresh air circulation in produce transport.

There is more to transporting fresh produce than temperature management. While temperature is critically important, equally …

Marine

Reliable Refrigerated and Intermodal Marine Transport.

Thermo King’s passive refrigeration technology is an autonomous concept for intermodal applications that combines the …