Active temperature-controlled

containers for air cargo

Air cargo

Designed for the pharmaceutical Industry

Pharmaceutical and biological compounds are among the most valuable temperature-sensitive products on the market. They need to be kept within extremely precise temperature ranges or risk losing efficacy – which can impact patients all around the globe.

Temperature-controlled containers enable precise end-to-end temperature control throughout every stage of the cold chain transportation cycle. This ensures that the pharmaceutical products being shipped inside are never affected by variable conditions experienced during the consignment journey.

Thermo King

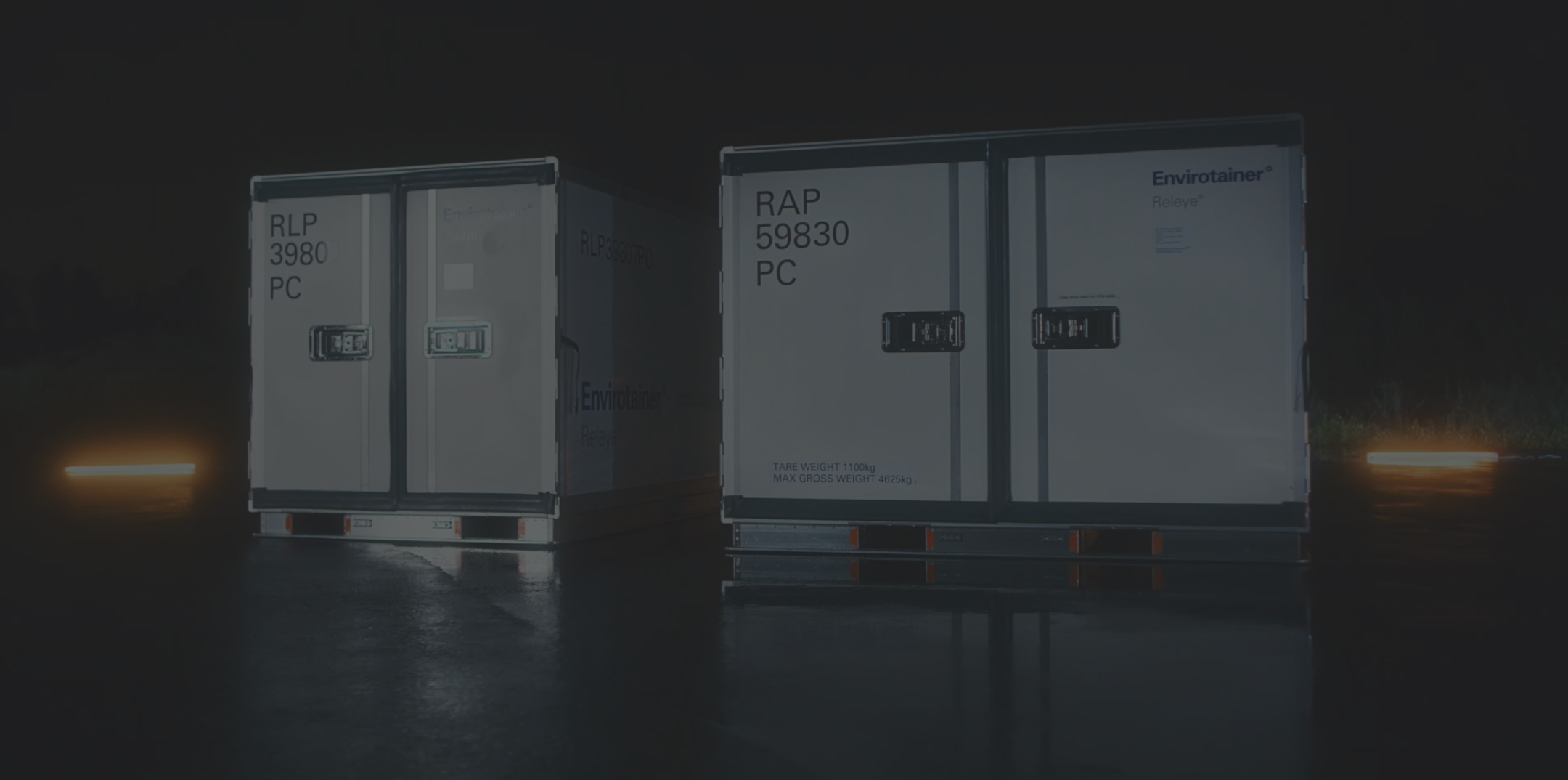

and Envirotainer

Thermo King, a leader in temperature-controlled transport and Envirotainer, a market leader in active containers for air transport, have designed active refrigeration units specifically for the pharmaceutical transportation industry.

Active refrigeration is contrasted with cooling methods like dry ice, which cannot be closely regulated and monitored. Thanks to these active refrigeration units, valuable and vulnerable medical cargo can quickly make its way around the globe, kept safe by active refrigeration technology made to meet the tightest regulations in the transport industry.

Two specialised units

The Air100-RNK e1 & Air200-RAP e2 refrigeration units are specifically designed to meet the critical shipping needs of the healthcare and aviation industries. They overcome the industry’s main challenges: the need for safe transport and precise temperature control. Both models utilize compressor cooling and electric heating technology to meet the extreme requirements of the pharmaceutical industry for shipments.

The containers maintain product temperatures in the +2 to +8 °C range, controlled room temperature range (+15 to +25 °C) or at any chosen set temperature between ±0 and +25 °C in nearly any ambient condition appearing along global shipping routes. This means life-saving medicines can quickly and safely make their way to patients around the world.

A global network of skills and expertise

Both refrigeration units have been certified by the European Aviation Safety Agency for airworthiness and compliance with applicable regulations. Following Civil Aviation Authority global aircraft safety and maintenance regulations, only air-certified Thermo King dealers may maintain, service and repair the Air100-RKN e1 and Air200-RAP e2 units. Our technicians, compliant with EASA/FAA regulations, work globally with Envirotainer repair stations on site, ensuring peace of mind for the healthcare and aviation industries and their customers.

Use case

Pharma Solutions

Broad range of GDP-compliant applications and services tailored towards the pharmaceutical industry, with cooling down to -70°C to protect vaccines.